11

PEOPLE FLOW |

ReinvenTing The elevAToR

Traveling more than 500 meters,

or 100-odd floors, in a continuous

elevator trip is challenging and doesn’t

really make sense using conventional

technology. At that point, the weight of

the several kilometers of rope needed to

hoist the elevator becomes an obstacle.

More ropes are needed just to lift the

weight of the ropes.

In a building this tall, the moving

masses of a single elevator hoisted

with steel ropes can be some 27,000

kilograms. This is equal to fitting ten

off-road vehicles inside the shaft and

shifting them along with the elevator.

Using KONE UltraRope for hoisting in

a similar shaft, the moving masses are

roughly 13,000 kilograms, or about the

weight of four off-road vehicles.

Limits set by ropes are a major

reason why most very tall buildings

have sky lobbies served by shuttle

elevators from the ground. Separate

elevators take people higher from these

lobbies in the sky. In the future, KONE

UltraRope will enable elevator travel all

the way from ground floor to penthouse

in a kilometer-high building in one

continuous journey.

“We are on the brink of something

big. In a sense, we have reinvented the

high-rise elevator,” says Pihkala.

KONE UltraRope is compatible with

all other KONE high-rise solutions so

it can be used to replace conventional

ropes in old buildings. And with the

new technology, the higher you go, the

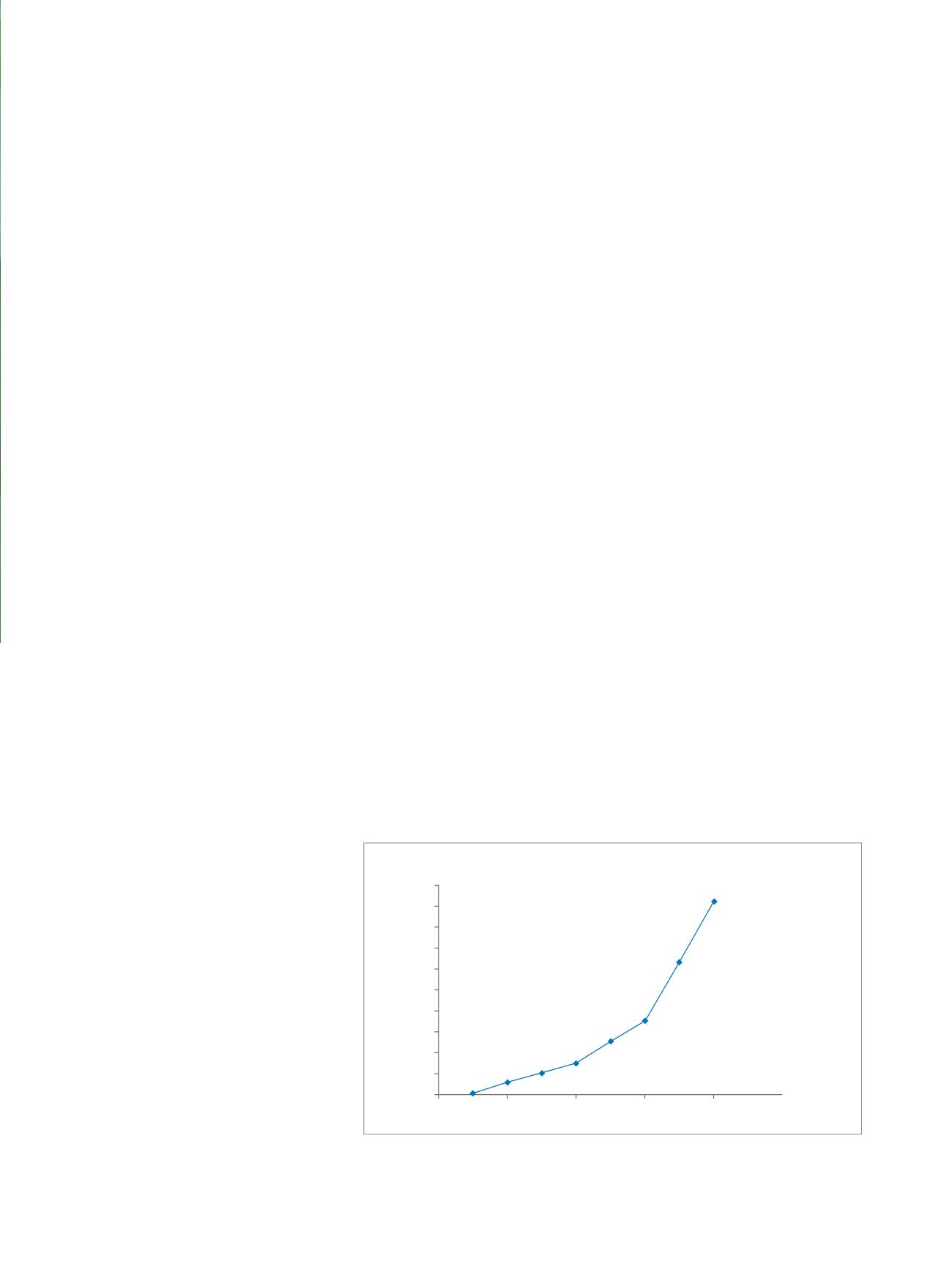

bigger the benefits. For example, the

energy savings for a 500-meter elevator

journey are around 15 percent versus

conventional rope. For an 800-meter

journey, the savings are over 40 percent.

some of the qualities that have been

measured.

no RusT, no weAR

Unlike steel, carbon fiber does not rust,

stretch or wear. The special coating of

the new rope makes lubrication un-

necessary, meaning environmentally

friendlier maintenance. Carbon fiber

also resonates at a completely different

frequency to most building materials.

This means KONE UltraRope is less

sensitive to building sway, and eleva-

tor downtime during strong winds and

storms can be reduced.

While typical high-rise elevator

ropes need to be changed at regular

intervals – no easy task in a tall build-

ing – the new technology enables a

rope lifetime twice that of conventional

ropes. KONE has also developed a real-

time rope condition monitoring system.

“We have a rope that works, is

reliable, and delivers on our promises,”

Pihkala beams. “This is a good place to

move on from.”

■

1km

KONE ULTRAROPE

™

WILL ENABLE

ELEvATOR TRAvEL OF UP TO ONE

KILOMETER IN THE FUTURE.

KONE UltraRope™ in

action, being tested at

the Tytyri high-rise

laborabory in Lohja,

Finland.

CoRe sTRengTh

In addition to being very light, carbon

fiber is strong and durable. It has already

revolutionized products in several other

industries, including aviation and sport-

ing equipment.

At KONE, the idea of creating a

carbon fiber rope came in 2004. “The

first prototypes were made by hand,”

says Pihkala. Actual research and

development began a few years later. It

wasn’t long before the rope was fitted

into a shaft at KONE’s Tytyri high-rise

testing laboratory in Southern Finland.

“We were surprised by how

problem-free it was,” says Pihkala.

“Often, there are a lot of problems

when you develop something com-

pletely new. But our faith in this started

to grow very quickly.”

The rope has since been tested

thoroughly both in real elevators and

in laboratories. Properties like tensile

strength, bending lifetime, material

aging and the impact of extreme

temperatures and humidity are just

PeRCenTAge %

elevAToR TRAvel heighT (m)

0,0

0

200

400

600

800

1000

5,0

10,0

15,0

20,0

25,0

30,0

35,0

40,0

45,0

50,0

AnnuAl sAvings in eneRgy ConsumPTion