KONE 2015 | SUSTAINABILITY REPORT

SAFETY

17

in different parts of the world and provide

educational material for our customers and the

general public to help equipment users stay

safe. Our safety mascots, Bob and Max, help

teach children about the safe use of equipment

through events, leaflets, and an online

animation and game.

Building owners and maintenance service

providers are responsible for making sure

equipment is professionally maintained and

kept in good condition. Building owners

should, for example, inform service providers

if they identify any recognizable hazards,

such as broken glass or sharp edges due

to vandalism. We work closely with our

customers to provide them with the tools to

recognize and deal with situations that could

lead to safety risks.

Active participant

The safety level of elevators, escalators,

and automatic building doors is largely

determined by national and international

safety codes and standards. KONE

contributes actively to the development

of codes and standards that aim to further

improve equipment safety. We also promote

safety through our involvement in industry

trade associations. Our experts have, for

example, been involved in the planning

and development of the extensively revised

main European safety standards for elevators

(EN 81-20 and EN 81-50) introduced in

2014, and the new European Lifts Directive

2014/33/EU, enforced from April 20, 2016.

A major concern for our industry is the aging

urban infrastructure systems in cities around

the world. In Europe, several countries have

adopted strict standards for improving safety

through modernization. Elevator modernization

is a critical issue that enhances safety and

accessibility by, for example, improving leveling

accuracy and the functioning of doors, and

providing a voice link to the service center. We

work with customers to find the modernization

solutions that best meet the requirements of

their buildings.

As a technology provider, KONE manufactures

equipment that meets applicable codes and

standards. Furthermore, our equipment often

includes additional safety features that exceed

the minimum requirements.

Safe at work

At KONE we have defined safety as our highest

priority. This means making sure each of our

employees has the necessary competence to

perform their work professionally and safely.

KONE’s Supplier Code of Conduct requires

all of our suppliers, including subcontractors,

to protect the health and safety of their

employees. We require both our employees

and subcontractors to follow our globally

defined rules and methods to protect their

own safety and that of anyone else who may

be affected by their activities.

KONE employees receive training on health

and safety, and safety is a key element in all of

our product and operations trainings. Toolbox

talks are used to communicate safety messages

to field employees. And for four years running,

KONE has organized a Global Safety Week with

a range of activities aimed to further boost our

safety culture.

Every manager is responsible to provide his

or her team with all the necessary means for

working safely. Managers perform regular

audits to measure compliance with KONE’s

policies, rules, and defined working methods.

Corrective actions are taken if deviations are

identified.

KONE also conducts process audits and

controls to identify possible obstacles to work

safety and if found, the work in question is

stopped until a safe method is approved.

Members of senior management teams

participate in workplace audits regularly.

Incidents, lost days per incident, and the

number of near misses are part of each

unit’s monthly reporting to global functions.

The underlying root causes are identified

and corrective and preventive actions are

implemented to prevent the accident or

near-miss from being repeated. Quarterly

global safety network meetings are used to

share lessons learned from accidents and near

misses, and safety managers gather monthly

to discuss concerns and share best practices.

Read more at

www.KONE.com/safety.IIFR DEVELOPMENT

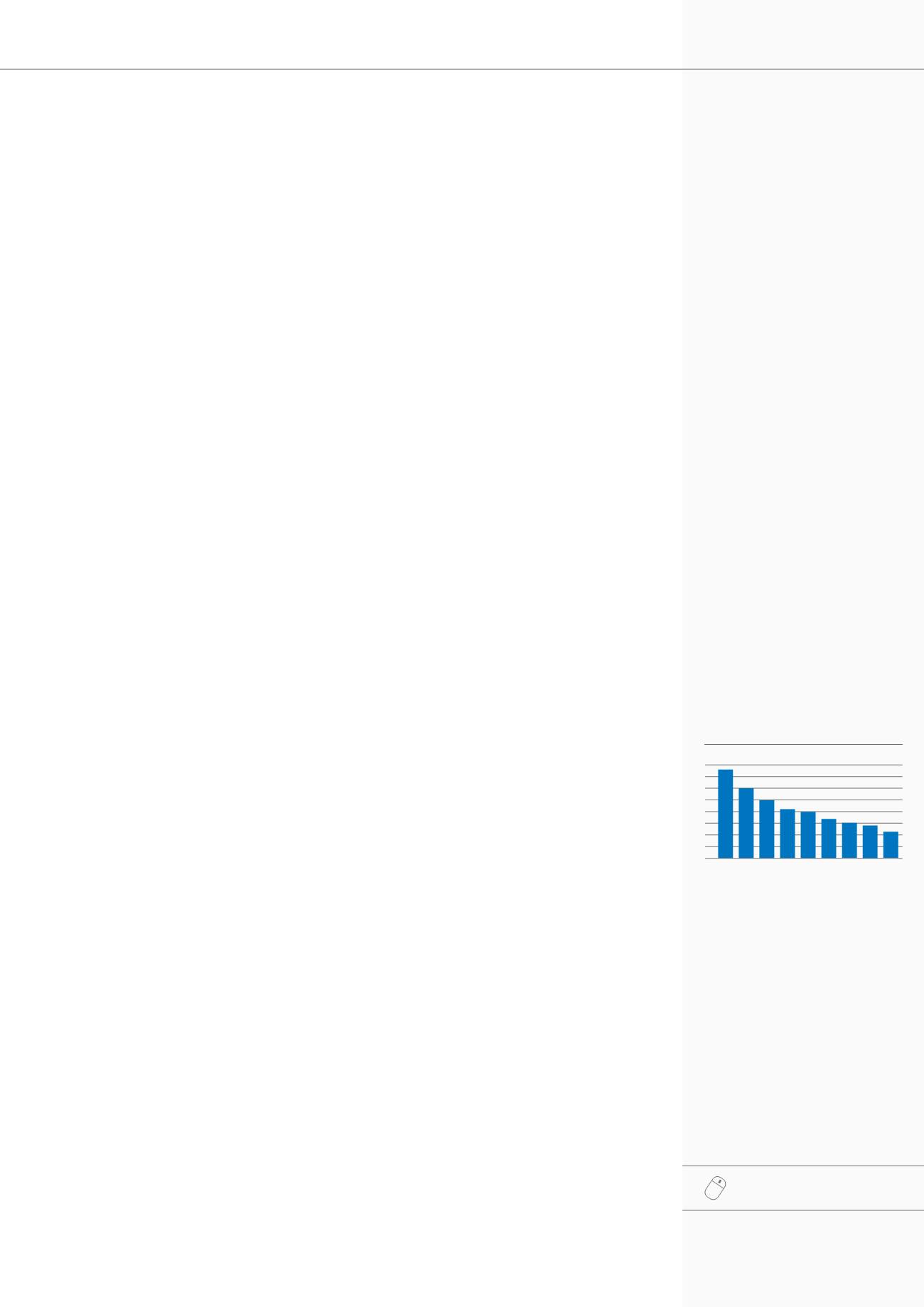

In 2015 the industrial injury frequency

rate (IIFR) among KONE’s employees

was down by 18% from 2014. As a

key performance indicator, KONE

tracks the number of lost time injuries

of one day or more per million hours

worked.

Industrial Injury Frequency Rate

development among KONE

employees

KONE tracks the number of lost time injuries

of one day or more, per million hours worked,

as a key performance indicator. The IIFR

covers KONE’s own employees.

2007 2008 2009 2010 2011 2012 2013

8

7

6

5

4

3

2

1

0

2014 2015

SAFETY TARgETS

AND ACHIEVEMENTS

• KONE’s ultimate goal is zero

accidents

• In 2015 our industrial injury

frequency rate (IIFR) was 2.3, down

from 2.8 in 2014

• Employees regard KONE as highly

committed to employee safety,

according to the 2015 results of the

annual employee survey Pulse.