KONE 2015 | SUSTAINABILITY REPORT

SUPPLY CHAIN

4 4

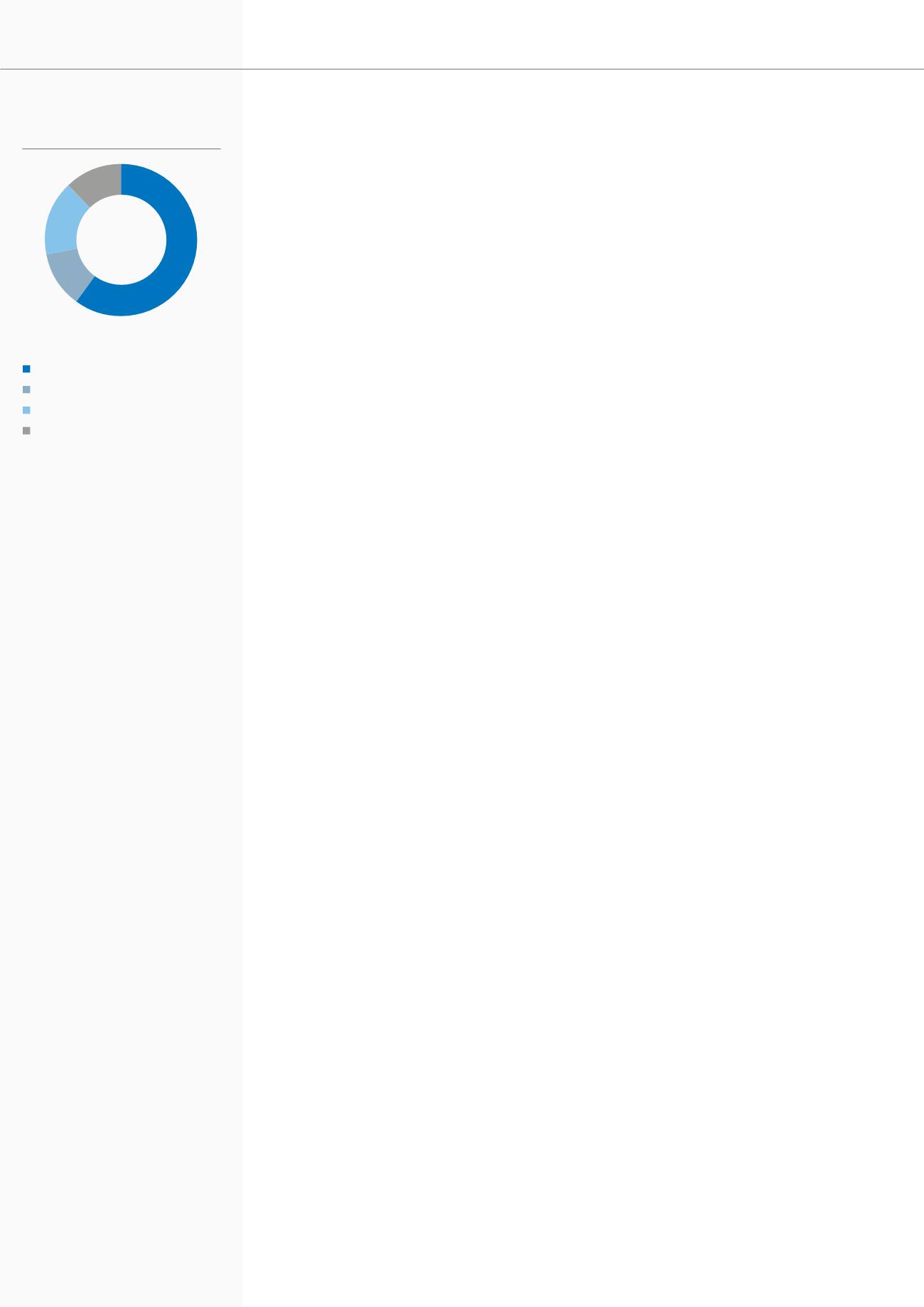

Total 3,853 MEUR

Direct materials and supplies

Subcontracting

Other production costs*

Other indirect costs**

60%

(60%)

12%

(12%)

14%

(16%)

14%

(12%)

Breakdown of material

and service costs

* Mainly freight and packaging costs

as well as other variable costs such as

utilities, tools and operatives related

costs.

** Relate to for example administration

expenses, covering IT, marketing,

trainings, and insurances.

Our suppliers and their sub-tier suppliers are a

critical part of KONE’s supply chain. Without

them, we could not provide high-quality

products and services to our customers. Just

as internal efficiency is essential, so is working

effectively with the approximately 20,000

suppliers who provide KONE with raw materials,

components, modules, and logistics and

installation services – not to mention other

suppliers who provide us with indirect materials

and services.

We only produce selected components

in-house. Our production consists largely of

the assembly of sourced components. The

main raw materials used in our elevators,

escalators, and automatic building doors are

various types of steel and stainless steel as well

as aluminum and copper.

We purchase approximately 80% of our

raw materials, components, and systems

supply for new equipment production from

approximately 100 suppliers, the majority of

which are located in the same countries as

KONE factories or distribution centers (see Top

10 Supplier Locations).

Managing the relationships with our

suppliers

We work closely with our suppliers to develop

our business, and our aim is to build a long-

term relationship with them. We manage our

suppliers according to a tailored approach that

evaluates their importance and criticality to

KONE. This is done through the regular, critical

assessment of multiple factors such as the

business scope and spend with the supplier,

the innovation potential of the supplier, the

criticality of provided materials or services, the

supply chain situation, and the investment or

integration level of KONE with the supplier.

Based on supplier status, our management

and measurement techniques include audits,

assessment and mitigation of supplier-

related risk, the employment of standardized

contractual agreements that include the KONE

Supplier Code of Conduct, the assessment

of supplier performance, and supplier

certification.

Supplier Audits

All of the main suppliers of direct materials to

KONE distribution centers or factories undergo

regular audits. All of KONE’s strategic suppliers

were audited in 2015. We review our audit

plan every year to prioritize and schedule audits

according to KONE’s business needs. The audits

are scheduled to check on changes in products

or production processes, validate follow-through

on improvement initiatives, assess quality and

environmental management systems, especially

when suppliers are not ISO certified, or pre-audit

the suitability of potential suppliers.

Assessing supplier risks

KONE’s sourcing risk monitoring system is

based on a thorough assessment of suppliers,

including analyses of their financial and

business viability, and their dependence on

business from KONE. We also work closely

with our strategic suppliers to find competitive

raw material price levels.

Supplier Code of Conduct

KONE requests all its suppliers to commit to

KONE’s Supplier Code of Conduct. The code sets

forth KONE’s global values. Suppliers are expected

to adhere to the code in their dealings with

KONE, their employees, and suppliers, as well as

third parties. KONE may terminate its contracts

with suppliers for failure to adhere to the code.

KONE’s Supplier Code of Conduct was

updated during 2015 and the revised

document is the basis of new contract

negotiations and contract updates with

existing suppliers.

The Supplier Code of Conduct includes the

following key element:

Legal compliance

– Compliance with local

laws and regulations.

Business conduct

– Compliance with

ethical conduct respecting human rights;

zero tolerance for bribery and corruption;

avoidance and active disclosure of conflicts of

interest; fair conduct of business with regard

to competition laws and regulations.

Labor and human rights

– Fair and equal

treatment of employees; non-usage of child

or forced labor; ensuring a harassment-free

environment for employees; compliance

with any applicable wage-related laws and

regulations; respect of employee’s rights to

TOP 10 SUPPLIER LOCATIONS

1)

China

Italy

Finland

United States

Austria

India

Czech Republic

Estonia

Germany

Mexico

1) Suppliers that provide products for

new equipment to KONE distribution

centers and factories

LONg-TERM RELATIONSHIPS WITH SUPPLIERS