26

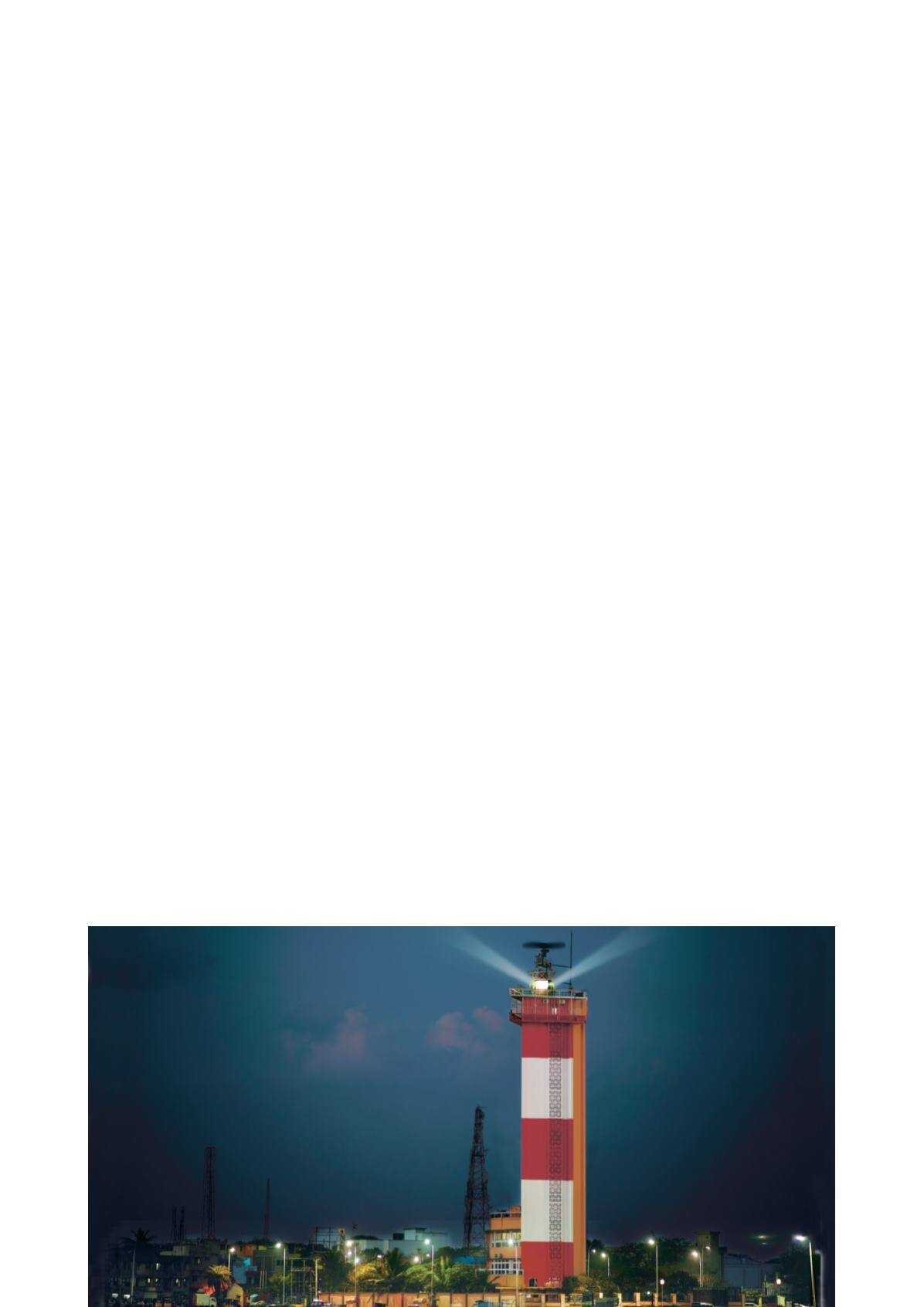

MADRASLIGHTHOUSE–CHENNAI, INDIA

Chennai’s beacon

shines again

The reopenedMadras Lighthouse on the east coast of the Indian subcontinent is one of the latest unique

structuresmodernizedby KONE.

Overlooking theBayof Bengal on theworld’s second-longest

beach stands a triangular edificepaintedwith large red and

white stripes in typical lighthouse fashion. After being closed

for 22 years, the legendaryMadras LighthouseonChennai’s

popularMarinaBeachwas reopened to thepublic at the end

of 2013 following a facelift and technical overhaul.

Built in1976, the iconic landmark is oneof the few lighthouses

in theworld–and theonlyone in India– tobeequippedwith

an electric elevator. Closed for security reasons for over two

decades, theMadras Lighthousehas nowbeen restored to its

original glory. It houses the Indianmeteorological department

andanewlyopened tourist attraction, a LighthouseMuseum

established throughapublic-privatepartnership.

Crowdpleaser

KONE equipped the 46-meter tall lighthousewith a new

elevator completewithemergency rescueequipment, intercom

and a floor announcement system. The KONEMiniSpace

™

elevator features a durable stainless steel car and a KONE

EcoDisc

®

hoistingmotor with regenerative drive features,

making it approximately 50percentmore energy-efficient

than the old unit it replaced.

Huge crowds linedup to see themuch-anticipatedopeningof

the lighthouse. Formany visitors, itwas their first opportunity

toadmire theBayof Bengal from sucha spectacular height.

“Wewereexcited to seea longqueueof visitorswaiting to

take theelevator to the viewinggalleryon inaugurationday.

Over10,000peopleusedour elevator in thefirst fourdays,”

says

K. Srinivasan

, KONEModernizationSeniorManager.

Fast-trackingwithprecision

KONEwas chosen toprovidea turnkey solutionbasedon

a soundunderstandingof end-user requirements in similar

modernizationprojects. The front wall anddoors of the

elevator car were custom-designed to accommodate

the existingentrancewall. Byadapting theelevator to the

site’s requirements, KONE accelerated the installation

process, thus accruing savings for thecustomer.

Due to its location, thedamp site isbuffetedbyheavywinds

and called for special safetyprecautions during installation.

Adding to thesephysical challenges, theentireprojectwason

a fast-track scheduleof 60days, includingdeliveryofmaterials,

dismantling theexistingelevator and installing thenewunit.

KONE carefully coordinated schedules and reviewed site

progressonadailybasis toensure thatworkwas completed

on time andmet establishedquality standards. Thorough

preparatoryworkwas carriedout in a timelymanner and

thehoistwaywas ready aheadof the arrival of equipment,

enabling the installation toproceed seamlessly.

“Wecompleted the installation from shutdown tohandover

of thenewelevator inonly28days,whichwas10days ahead

of the timeallocated for installation,” revealsSrinivasan. KONE

will alsohandle themaintenance of the new elevator.