engineering fields. This multidisciplinary

approach is essential especially as right

now, no one knows if the likes of Apple,

Google and Microsoft will be collaborators or

competitiors,” adds Jennings.

Potential competition goes beyond

products and into long-standing business

models. The likes of Uber, Lyft, Relayrides

and Getaround present the sharing economy

as a viable alternative to owning a car. Many

people wouldn’t consider life without a car,

but in growing, urbanized societies populated

by a millennial generation who have grown

up renting, leasing and streaming rather than

owning, it’s feasible that new car sales could

face a long-term decline.

The impact of digitalization on the industry

caught the attention of the public at the 2015

Consumer Electronics Show (CES), which

was dominated by the connected car. Both

established companies and newcomers used

CES 2015 to demonstrate new technology

and new business models, largely based on

the Internet of Things (IoT).

For example, Nvidia unveiled a new Tegra

X1 processor specifically designed for tablets

and car dashboards, AT&T and Samsung

announced a research partnership focused

feature

“We are shifting focus

to work with software

and standards instead

of specific hardware to

be sure our cars stay

relevant in the future.”

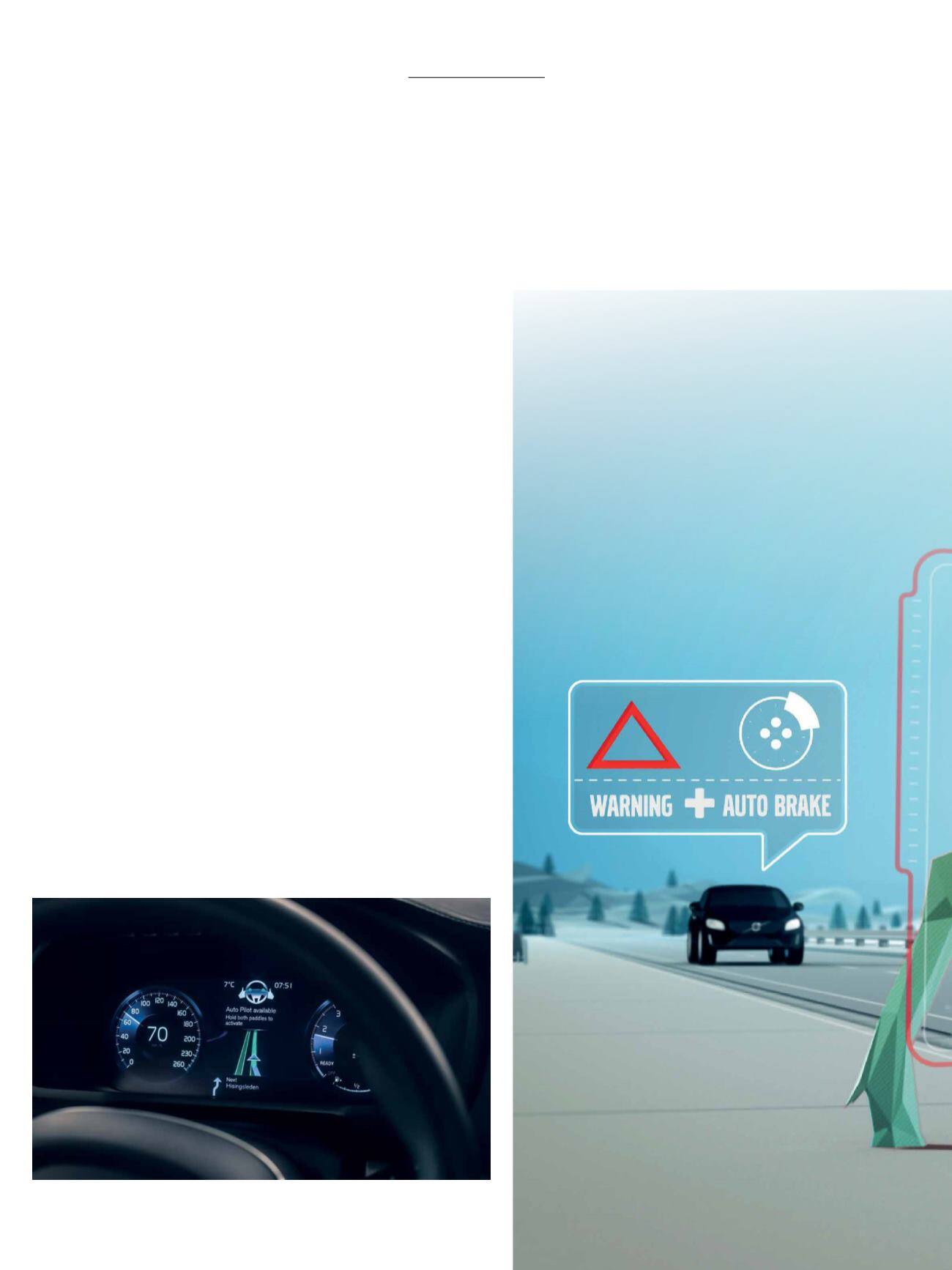

Auto pilot: Mode

of the future.

on the connected car, while Volvo Cars

presented a vision where connected cars and

cyclists could be warned of dangerous close

encounters.

ADAPTING TO A DIGITAL WORLD

“We are looking at how the safety tradition

of Volvo can continue into the era of the

connected car,” says

Jonas Rönnkvist

,

Director of Business Development & Strategy

for Consumer IT Services at Volvo Cars. “This

is why we are currently pioneering the field

of “Connected Safety” as we call it. With

sensors, our cars have the possibility to detect

potentially dangerous situations, for instance

if there is slipperiness on certain sections

of road. Soon they will be able to share this

information in real time, through the cloud,

with other cars and thereby contribute to a

safer driving environment.”

He says everyone at Volvo Cars understands

the challenge ahead.

“Traditionally it takes a couple of years to

develop a new model, followed by a five-to-

seven year production run, with a further

twenty years of support and service. That

thirty year time frame simply doesn’t fit into

the speed of change in the digital world.”

Rönnkvist uses the example of how

quickly consumer technology is changing

to highlight the challenge ahead. “If we

incorporate a specific connector into a new

car design, we run the risk of that connector

being obsolete by the time the car hits the

market. Just think about what phone you

were using a couple of years ago, and what

has changed in that time. We are shifting

focus to work with software and standards

instead of specific hardware to be sure our

cars stay relevant in the future.”

BIG DATA IN THE VALUE CHAIN

Away from the public eye, a group of IoT

technologies otherwise known as the

‘Industrial Internet’ looks set to alter the way

of working for the entire supply chain, from

Original Equipment Manufacturers (OEMs)

right through to operations on the factory

floor.

Big data analytics should help brands

and OEMs to make sense of the oceans of

6